Subsea cutting

Mission-critical cutting equipment delivering predictable performance

Overview

Seatools: Your Cutting-Edge Subsea Technology Partner

Developing effective underwater cutting equipment demands a distinctive fusion of expertise encompassing subsea electric drives, advanced control systems, cutting technology (including diamond wire), and, in certain cases, excavation technology. Within the specialized domain, Seatools positions itself as a subsea technology partner. Our collaborative approach entails partners providing their cutting technology or concepts, while Seatools transforms these ideas into tangible subsea equipment solutions. Serving as a proficient system integrator, we leverage our profound knowledge in subsea electronics, hydraulics, and controls to bring our clients’ core technology concepts to fruition. Our track record, highlighted by the successful implementation of mission-critical subsea cutting equipment like the Koersk saw control system and the Barracuda response tool, underscores the effectiveness of this partnership model.

- Expertise

-

- Subsea cutting equipment

- Advanced saw control systems

- Value creation

-

- Cutting tools that deliver predictable performance

- Operational risk reduction thanks to extensive cutting operation automation

- Cutting equipment based on standardization

- Track record

-

- Control systems for mission-critical subsea saws

- All-electric subsea diamond wire saw with depth rating of 10,000 feet

Are you in search of a subsea technology partner capable of bringing your cutting technology to life?

HOW WE CREATE VALUE

-

Cutting tools that deliver predictable performance

In capital-intensive offshore cutting operations, reliability and predictability are crucial, particularly in remote and challenging environments. Seatools stands by its “first-time-right” philosophy, backed by ingrained principles and routines. This approach guarantees flawless performance from the initial operation, enabling seamless functionality and swift start-ups in demanding offshore settings.

-

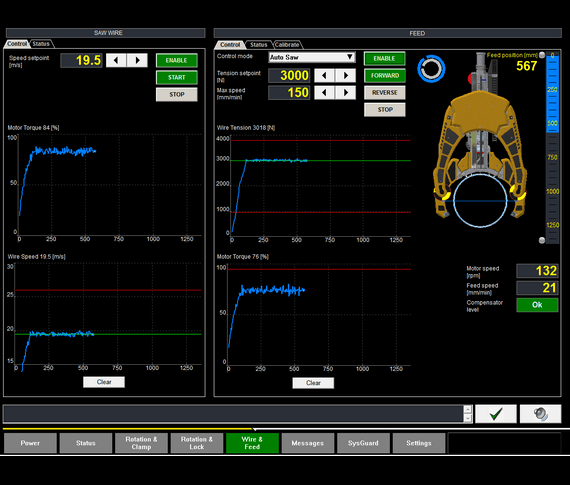

Operational risk reduction thanks to extensive automation of cutting operations

Our underwater cutting equipment integrates sophisticated monitoring and control systems. in a highly automated manner. Cutting automation greatly enhances operational reliability, as it rules out the risk of overfeeding, and achieves optimal cutting speeds.

-

Cutting equipment based on standardization

Our extensive technology toolbox, comprising standardized modules and components, empowers us to deliver cutting equipment solutions in a very efficient way. This toolbox offers numerous advantages, including reduced lead times, competitive pricing, and the assurance of reliable, proven technology that consistently delivers predictable performance.

Would you like to discuss your project with our experts? We gladly review your project and exchange ideas in a way that takes your project forward.

TRACK RECORD

A track record of mission-critical equipment

- Date:

- August 2014

- Project duration:

- 7 months

- Client:

-

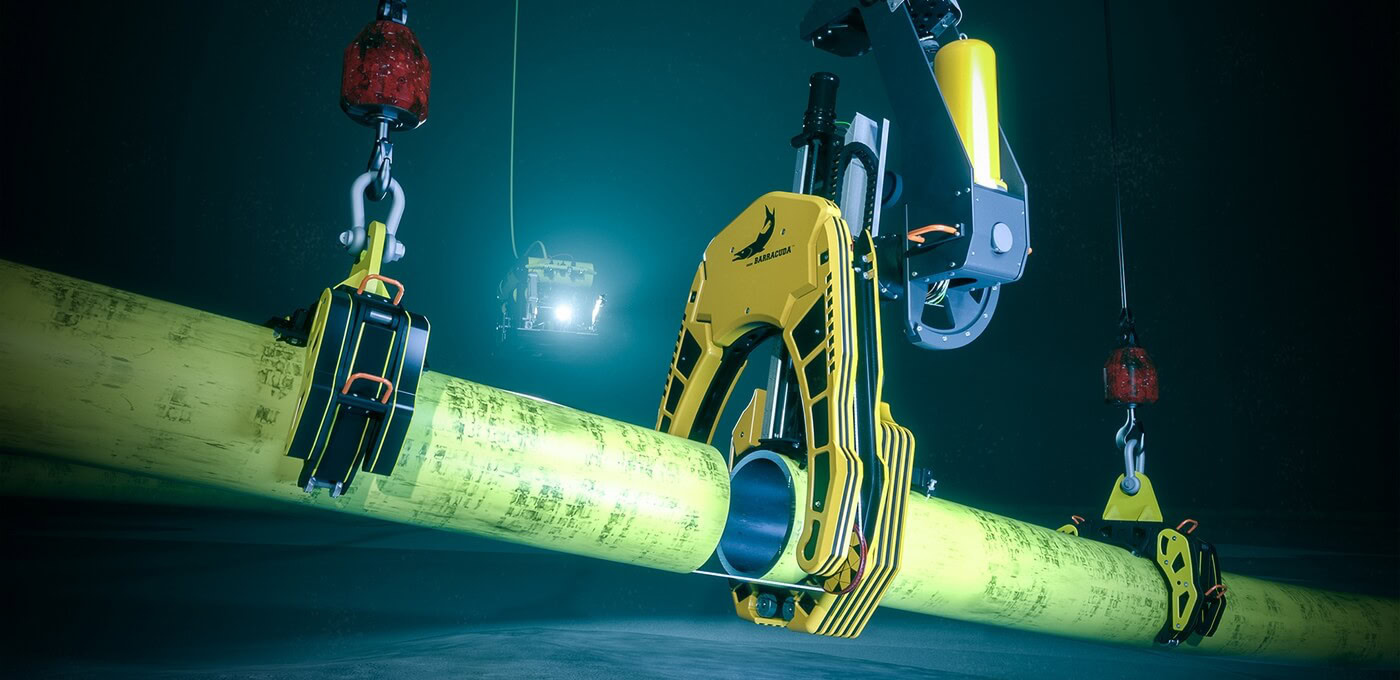

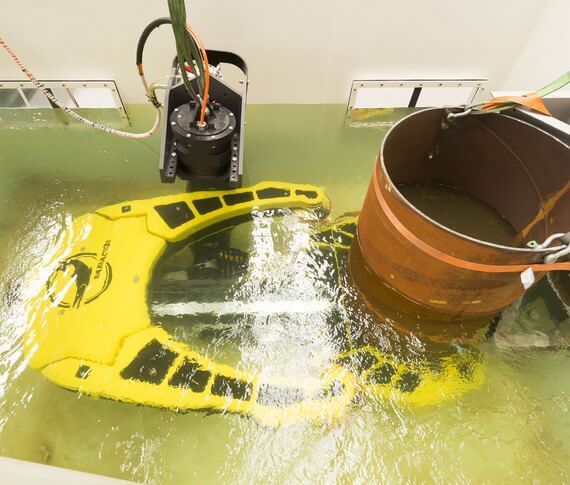

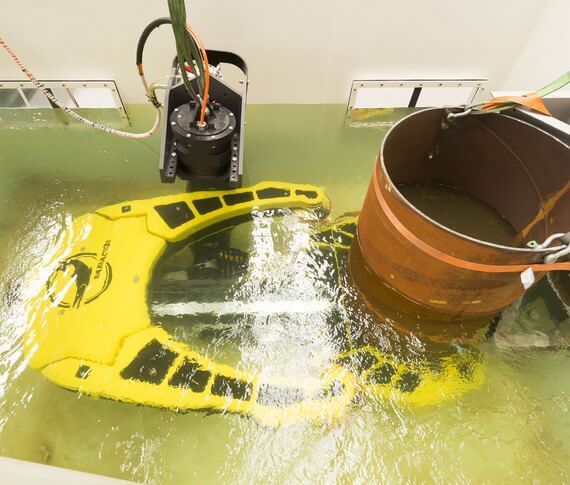

Dedicated all-electric subsea diamond wire saw designed as response tool in water depths of up to 10,000 feet

The Barracuda is a response tool that was specifically designed for subsea cutting in emergency situations. During the development of the saw, carried out by 1Diamond and Seatools, two criteria weighed in heavily: reliability and flexibility.

This resulted in an all-electric underwater diamond wire saw, executed with a high degree of cutting automation and various features that help cut the connection between seafloor and platform.

- Date:

- June 2001

- Project duration:

- 6 weeks

- Client:

-

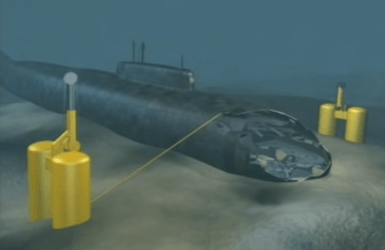

Saw control system

For the Koersk salvage operation, an oscillating rope cutter was applied to cut the heavily damaged submarine’s nose from its hull. The cutter was actuated by two opposite cylinders, installed on each side of the submarine.

Seatools delivered the complete monitoring and control system of the saw system. The monitoring and control system, which was developed and delivered within 6 weeks only, performed very well and enabled Smit to successfully salvage the Koersk.

CONTACT

Would you like to discuss your project with our experts?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75