SubseaHPUs

Subsea hydraulic power for every application

Overview

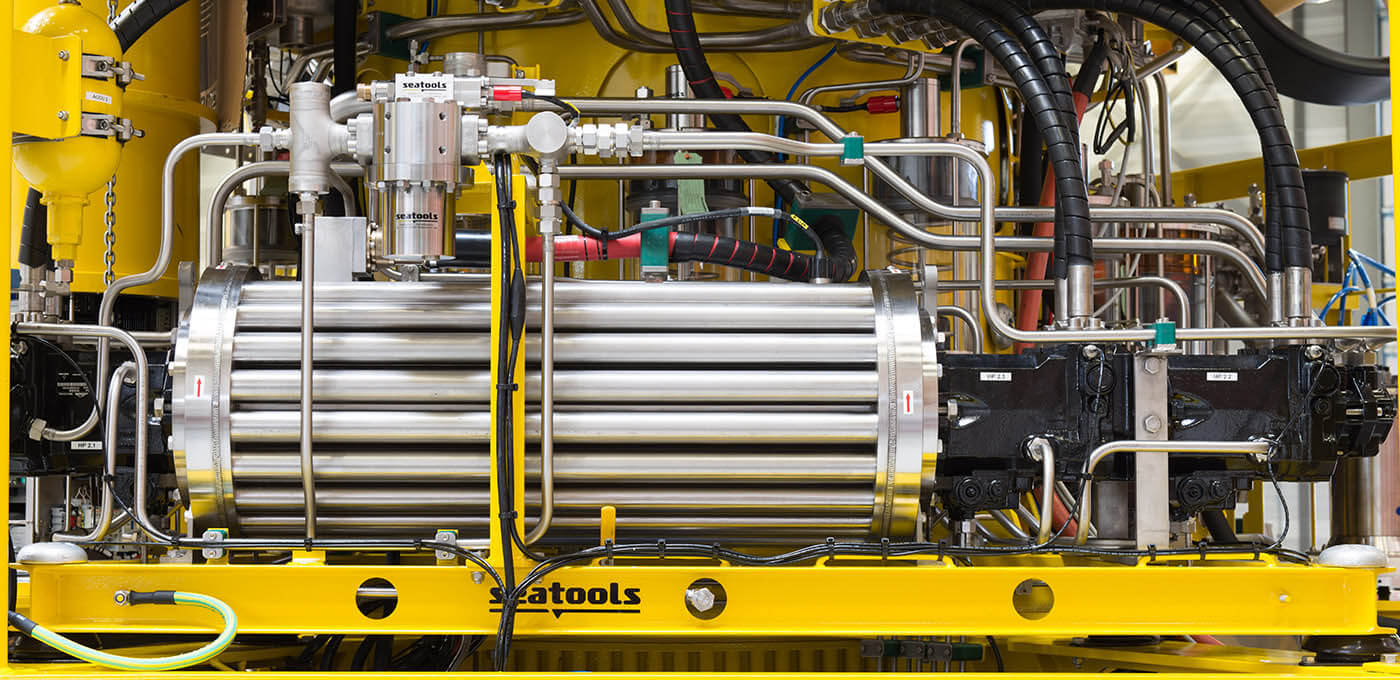

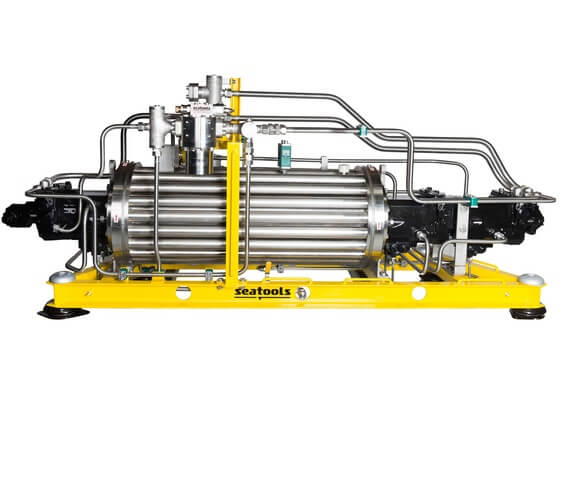

Seatools provides subsea hydraulic power by means of standardized and custom-made subsea HPUs

Thanks to our background in the design and construction of extremely reliable ROVs that are able to endure the toughest conditions, Seatools acquired a strong capacity and knowledge base in the development of reliable, compact, and efficient subsea HPUs. Because subsea hydraulic power units represent a critical element in the hydraulic system of an ROV, our background has helped us develop a strong sense for the appropriate balance between redundancy level and the cost of achieving redundancy.

We are not only capable of delivering subsea hydraulic power units for the propulsion of subsea vehicles; we also design and build various other types of subsea HPUs, such as for subsea control modules, monitoring and control systems, dredging applications, and ROV tooling. The combination of our standardized product range with our customized offering guarantees our ability to provide subsea hydraulic power for any of your applications.

Subsea HPUs – Buyers guide

Learn more about SHPUs and the possibilities for your project.

Download PDF- Expertise

-

- Subsea HPUs for any subsea application, including: subsea vehicles, control systems, dredging equipment, ROV tooling

- Subsea HPUs for Subsea Control Modules (SCM)

- Subsea hydraulic systems

- Value creation

-

- A suitable subsea HPU for every application

- An offering that extends far beyond SHPUs

- Modular designs for easy installation and maintenance

- Track record

-

- Delivered 200+ subsea HPUs

- Delivered SHPUs from 0.2 to 400 kW

- Battery-powered subsea hydraulic power packs

Would you like to discuss your project with our experts? We gladly review your project and exchange ideas in a way that takes your project forward.

SCOPE

- Delivery of standardized subsea HPUs

- Delivery of custom-made subsea HPUs

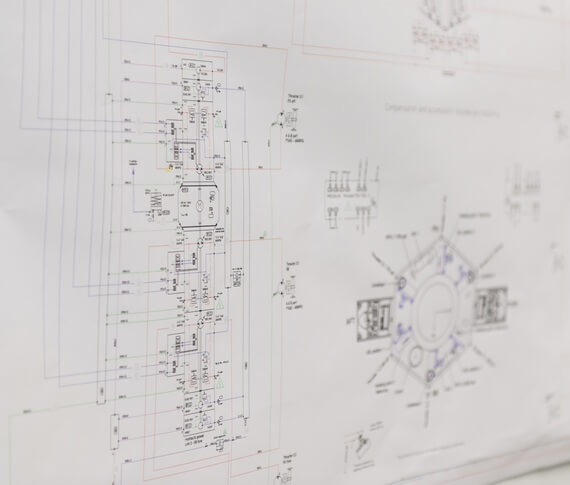

- Feasibility and conceptual design

- Subsea HPU maintenance and repair

A range of field-proven subsea power units

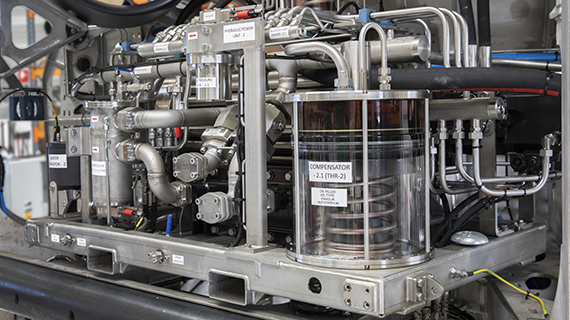

Our standardized subsea power units are field proven, highly reliable subsea power packs that can be applied to a wide range of subsea applications. Our designs are based on numerous years of field experience gained from installing SHPUs on our industrial grade subsea equipment – which operate under harsh conditions – and our power packs come in a wide variety of possible configurations and options. Furthermore, Seatools supplies auxiliary hydraulic system components such as compensators, hydraulic filters, and pressure pods. Upon request, we deliver turnkey, tailor-made subsea hydraulic systems for your application.

Subsea power units that meet your specifications

Seatools has an extensive track record in the design and delivery of custom-made subsea hydraulic power units. We have delivered subsea HPUs in a wide variety of configurations, and with power ratings ranging from 0.2 kW to 400 kW. Our customized power units can be designed to meet any specification, with variations in required flow and pressure outputs, depth rating, allowable weight and size, applied hydraulic fluids, cooling, required redundancy, and quality standards.

Pursuing optimal subsea hydraulic power supply solutions

Seatools is capable of and experienced in conducting (conceptual design) studies to analyze and/or develop highly specific subsea power units. This type of studies is typically applied to one-of-a-kind applications, such as SHPUs that power Subsea Control Modules (SCM). Example study subjects include redundancy level / CAPEX optimization, application of unconventional control fluids, interface studies, failure behavior optimization, durability, and power management.

Preserve the performance of your subsea power unit

We perform maintenance and repair on self-manufactured subsea hydraulic power packs. In addition to our power units, we also perform maintenance and repair on full-fledged subsea hydraulic systems.

HOW WE CREATE VALUE

-

A suitable subsea HPU for every application

Thanks to the combination of our standardized product range and our ability to deliver custom-made HPUs, we can supply a subsea power pack for every application. We deliver SHPUs ranging from simple and rugged versions able to perform in vibration-intensive environments (such as subsea trenchers) to highly redundant SHPUs for subsea control modules with a design lifetime of more than 25 years. These highly redundant SHPUs are designed in compliance with API 17F and the appropriate SIIS levels.

-

One-stop shop for subsea hydraulics

On top of providing subsea hydraulic power units, Seatools is supplier of all related components, such as subsea hydraulic filters and compensators. In addition, we provide full-fledged hydraulic systems (including controls) and can simulate an entire electro-hydraulic system in order to guarantee first-time-right delivery when the system is commissioned.

-

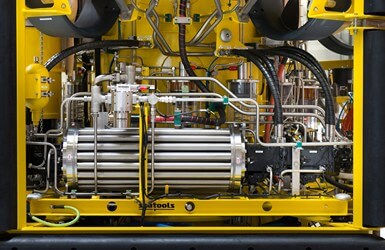

Modular designs for easy installation and maintenance

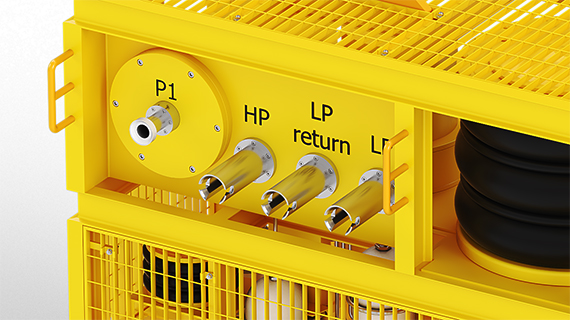

Our modular SHPU designs feature hydraulic piping. This facilitates easy connection to and removal from subsea vehicles and systems, thus enabling effective installation and maintenance.

Seatools is a one-stop shop for subsea hydraulics. Our offer includes subsea HPUs, related components such as subsea compensators and hydraulic filters, and full-fledged subsea hydraulic systems.

Standardized SHPUs

Plug-and-play units

- Flow rate range (l/min)

- Maximum pressure range (bar)

- Depth rating (msw)

- Integrated compensator

- Flow rate range (gal/min)

- Maximum pressure range (psi)

- Depth rating (ft)

- Integrated compensator

TRACK RECORD

A selection of our dozens of successfully delivered subsea HPUs

- Project duration:

- 5 months

-

SHPU to power mission-critical pre-piling template

In order to have full insight and control during the offshore piling operations that were part of the construction of the Beatrice OWF, Seaway Heavy Lifting contracted Seatools for the design and delivery of a piling template instrumentation and control system.

The scope of supply included the complete (subsea) hydraulic system which consisted of a large number of hydraulic actuators. In order to power the entire subsea hydraulic system, Seatools applied a field-proven Seatools SHPU.

- Project duration:

- 12 months

- Client:

-

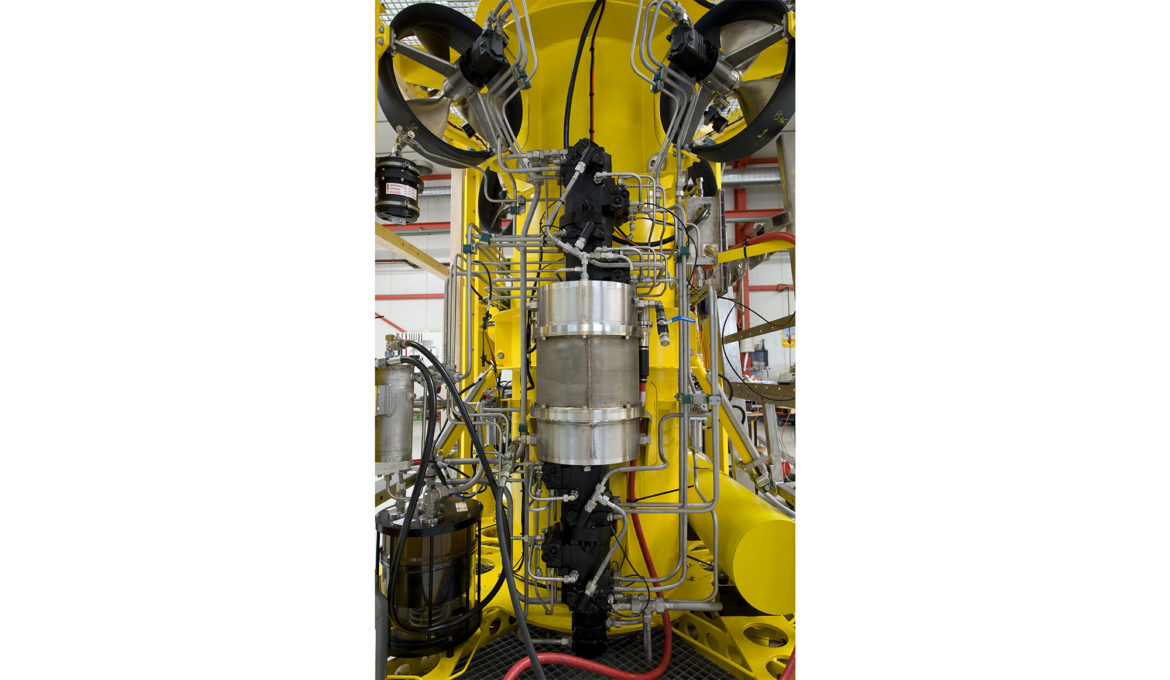

The ROV 7: a state-of-the-art fall pipe ROV that achieves extremely reliable rock installation operations

The ROV 7 fall pipe ROV was built for Van Oord’s new fall pipe vessel Braveness. It integrates all of Seatools’ knowledge and capabilities in the field of fall pipe ROVs, and represents the state of the art regarding custom-built ROVs.

In order to power the ROV’s propulsion system and various related systems, the ROV was equipped with two 225-kW ROV HPUs. The power units feature a modular design allowing for effective installation and maintenance.

- Project duration:

- 3 months

- Client:

-

Battery-powered subsea HPU for autonomous monitoring and control system

In order to monitoring the twist, tension, and torsion in the cables connected to an abandonment and recovery hook, as well as to control the opening and closing of this hook, Allseas approached Seatools with a request for a monitoring and control system.

As no cables for power and data transmission were allowed, Seatools had to develop an autonomous system. We met this challenging requirement by powering the system with a battery-powered subsea HPU, while acoustic modems enabled data communication.

- Project duration:

- 7 months

- Client:

-

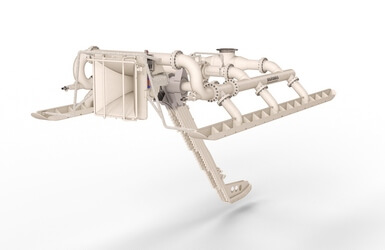

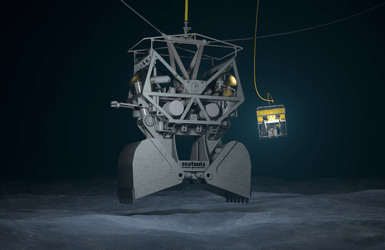

Hydraulic power for a highly effective subsea pipeline trencher

The Arthopod 600 is a subsea pipeline trencher suitable for pre- and post-lay subsea trenching. For this project, Seatools developed an innovative subsea pipeline trenching technique that efficiently creates large trenches in hard soils.

In order to power the vehicle’s propulsion system, its cutter head, and its cutter drum, Seatools developed and installed two power packs that each provide 300 kW of power.

- Project duration:

- 5 months

- Client:

-

Powering a subsea trenching pioneering machine

The Jetting Bull is one of the first towed subsea cable trenchers ever built – a truly pioneering project in the field of subsea cable trenching at its time of completion.

For the remote control of the jet fingers, a subsea hydraulic power pack – including hydraulic compensator – was incorporated in the Jetting Bull.

- Project duration:

- 13 months

- Client:

-

Extremely productive deep-water dredging at very high accuracy levels

Boskalis and Tideway required a new deep-water dredging method to excavate in challenging soil conditions at a water depth of 150 meters. To this purpose, the Grab Excavation System (GES) was developed.

In order to power this piece of heavy-duty subsea equipment, Seatools executed the grab with two subsea hydraulic power packs, each at a power rating of 200 kW. This level of power is used to drive the clamshell actuation system and the vehicle’s propulsion system.

- Project duration:

- 18 months

- Client:

-

Subsea HPU for a highly effective multipurpose inspection ROV

The ROHP II is a multipurpose inspection ROV designed for inspection, sampling, surveys, and light intervention tasks in waters with strong currents and poor visibility, such as the North Sea.

In order to power the ROV’s propulsion system, which consists of 8 thrusters, as well as the various auxiliary systems like the on-board jetting pump and tether winch, a 100-kW ROV HPU was installed on this ROV.

- Project duration:

- 11 months

- Client:

-

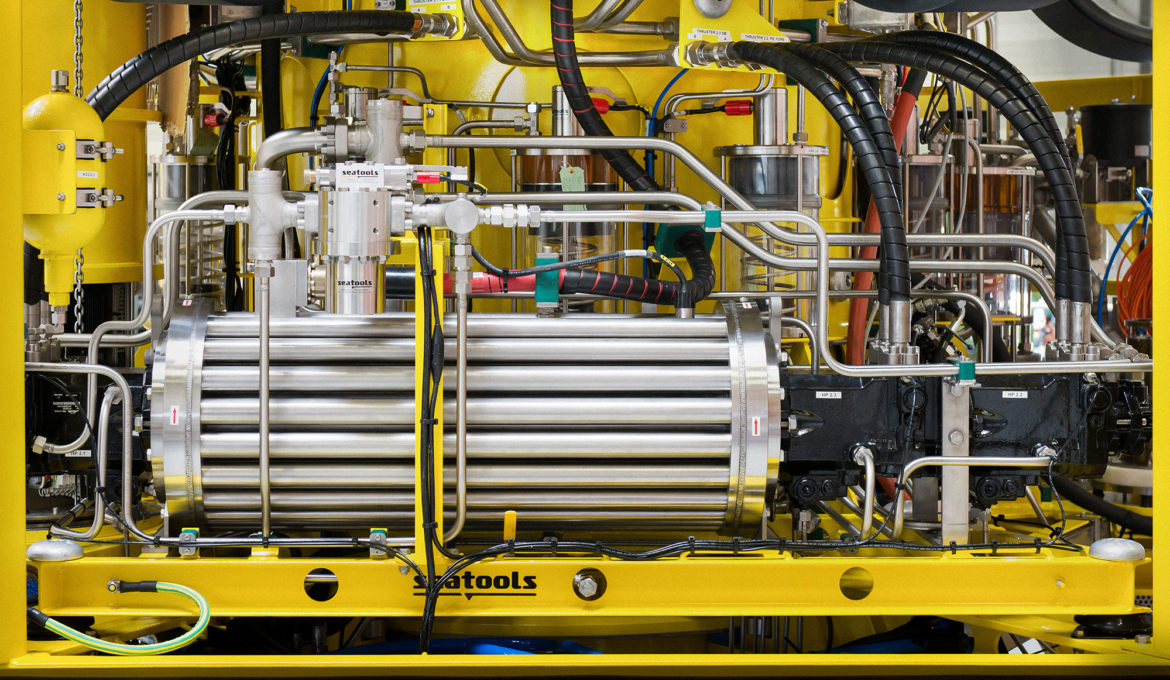

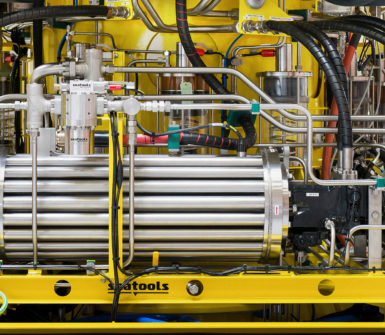

Significant operational efficiency gains from revolutionary integrated survey ROV technology

A highly automated fall pipe ROV with integrated survey ROV. The survey ROV features full DP functionalities, and can dock and undock fully automatically in order to perform direct post-process surveys, resulting in major cost savings.

Both the main ROV and the survey ROV feature electro-hydraulic drive configurations. The main ROV is equipped with two 130-kW ROV HPUs, while the survey ROV is powered by a single 60-kW power unit.

- Project duration:

- 13 months

- Client:

-

A highly reliable fall pipe ROV capable of performing multiple seabed preparation tasks

The Flintstone FPROV is one of the largest, most powerful, and versatile ROVs that Seatools ever built. The ROV can be equipped with a mass flow excavation tool to facilitate high-volume excavation tasks. Moreover, a seabed grader for precision seabed grading can be added.

In order to power the vehicle’s propulsion system, the FPROV is equipped with three vertically mounted power units that deliver 120 kW of hydraulic power each.

- Project duration:

- 5 months

- Client:

-

ROV HPU for a compact and easy-to-transfer FP ROV system

This highly compact fall pipe ROV was completed in 2009 for Jan de Nul. The system’s compact design facilitates easy transportation and use on various of our clients’ vessels. The ROV is capable of fully automated dynamic positioning.

Powering the four installed hydraulic thrusters, as well as the auxiliary equipment (such as equipment for surveys), Seatools equipped this ROV with a single, vertically oriented 75-kW ROV HPU.

- Project duration:

- 6 months

Minimum power plant downtime thanks to effective cleaning

As part of a major overhaul project at Hong Kong’s Black Point Power Plant, the cooling water intakes were scheduled to be cleaned of a 25-centimeter-thick layer of biofouling. The customer’s main concern – safety and a minimum of downtime – demanded a dedicated underwater cleaning machine.

Seatools developed a dedicated Remotely Operated Cleaning Machine (ROCM) that completed this operation with success. The machine has an electro-hydraulic drive configuration that incorporates a 140-kW ROV HPU.

- Project duration:

- 9 months

- Client:

-

Effective positioning of submerged tunnel segments

For the construction of the Busan-Geoje tunnel, Strukton was awarded the construction, immersion, and accurate positioning of tunnel segments. The crucial importance of the accurate positioning of tunnel segments required the development of a Tunnel Segment Measurement System (TSMS).

For the actuation of a hydraulic cylinder – required to provide a constant pressure – and to drive a small constant tension winch, a 200-watt subsea hydraulic power pack was installed on each measurement unit.

Contact

Would you like to discuss your project with our experts?

CONTACT FORM

OTHER CHANNELS

- General

- +31 (0) 186 68 00 00

- info@seatools.com

- Sales

- +31 (0) 186 68 00 00

- sales@seatools.com

- Service (outside office hours, emergency only)

- +31 (0)186 65 00 75